The key to organizing threading lies in the construction organizer. The construction organizer should: understand the overall structure of the wiring system and do not cross the wrong route; Be able to clearly distinguish various cables to be laid, and do not use the wrong cable; Be familiar with the pipeline through which the cable passes, and have rich threading experience; Know how to prevent typical problems affecting threading quality and progress; Understand the special requirements for cable laying of generic cabling project; The idea is clear, the information points are grouped and laid group by group, without more penetration or omission; Each group shall not exceed 20 information points, otherwise the amount of cables to be laid at the same time is large, and the laying is laborious, which is easy to cause cable damage, winding and knotting, which will greatly affect the progress; Mark carefully and record the length scale; Strictly organize the test, and use the detection instrument to measure the on-off condition of each cable.

2. Preparation before generic cabling Construction:

Try to find a cooperative and reliable construction team to thread. The construction organizer should be clear-minded and have a sense of responsibility. For the construction team cooperating for the first time, send someone to keep an eye on it. List the employment plan according to the actual situation, and apply to the manager for the remuneration prepared for the threading construction team based on the employment plan. The threading schedule and quality assurance measures shall be listed according to the completion time of pipe trench and the time requirements for subsequent wiring system installation, decoration and capping.

The threading inspection shall be strictly carried out before threading. For specific requirements, see the corresponding pipe groove inspection requirements. The pipe groove quality problems that seriously affect the threading quality and progress include: small pipe groove specification; There are burrs at the interface; Blocking and ponding of buried installation pipe trench; The buried pipe trench must be fully threaded before threading. Documents to be prepared include: wiring system diagram; Wiring system plan; Threading technical requirements and blank threading report.

3、 Guarantee measures for construction quality

(1) The detailed drawings in the design stage shall be well prepared, and the drawings are very important. Don't think it's very simple. A good generic cabling system design drawing can save your wiring time and some on-site problems encountered in the process of generic cabling engineering system. Those who have done building generic cabling system engineering know that there is not only weak current in the building, but also strong current, fire fighting, air conditioning, etc.

(2) During the construction process, the construction plan shall be made to cope with continuous changes.

(3) the progress of other parts of the whole project shall be known in time before the construction plan can be adjusted in time.

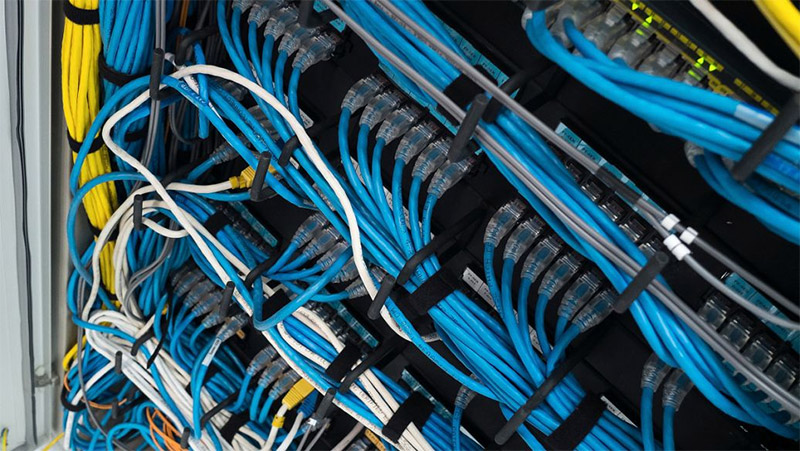

(4) Construction personnel shall be strictly required. The line shall be neat and clear.

(5) make labels.

97506075

97506075

Wechat QR code